Friday, January 2, 2026

What Is Gas Transfer Efficiency (GTE)?

1. What Is Gas Transfer Efficiency?

Gas Transfer Efficiency (GTE) describes how much of an injected gas actually dissolves into the water compared to how much gas is supplied.

Simple definition:

GTE (%) = (Gas dissolved in water ÷ Gas injected) × 100

If you inject 100 units of oxygen and only 15 units dissolve, your GTE is 15%. The remaining 85% is lost to the atmosphere.

Why GTE matters

Low GTE means:

Higher energy consumption

Higher gas consumption

Lower dissolved oxygen stability

Inconsistent biological results

High GTE means:

Lower operating costs

Faster oxygen delivery

Stable DO levels

Improved biological efficiency

2. What Controls Gas Transfer Efficiency?

Gas transfer efficiency is governed by physical and chemical laws, not marketing claims. The key drivers are:

1. Bubble size

Smaller bubbles = higher surface area per unit of gas

2. Bubble residence time

The longer a bubble stays in water, the more gas can dissolve

3. Gas–liquid interface stability

Stable interfaces allow diffusion instead of rapid escape

4. Pressure and solubility

Higher pressure increases gas solubility (Henry’s Law)

5. Water chemistry and temperature

Warmer water holds less gas; biofilms reduce transfer efficiency

3. Gas Transfer vs Oxygen Transfer Efficiency (OTE)

You may also encounter Oxygen Transfer Efficiency (OTE), a specific case of GTE used in aeration and wastewater.

GTE → applies to any gas (oxygen, ozone, CO₂, nitrogen)

OTE → specific to oxygen systems

The underlying physics is the same.

4. Comparison of Common Oxygenation Technologies

4.1 Surface Aerators

How they work:

Agitate water surface to pull air into water

Typical GTE:

🔻 2–5%

Limitations:

Extremely poor gas transfer

High energy consumption

Oxygen escapes almost instantly

Creates turbulence but not stable DO

Best suited for:

Emergency aeration, not precision oxygen control

4.2 Coarse Bubble Diffusers

How they work:

Large bubbles (>3–5 mm) released from the bottom

Typical GTE:

🔻 5–10%

Limitations:

Large bubbles rise fast

Very short contact time

Most gas escapes unused

Common mistake:

Assuming “more bubbles” = more oxygen (it doesn’t)

4.3 Fine Bubble Diffusers

How they work:

Smaller bubbles (0.5–2 mm) increase surface area

Typical GTE:

⚠️ 15–30%

Limitations:

Still buoyant — bubbles rise

Membranes clog over time

Performance degrades with biofilm

Industry reality:

Often marketed as “high efficiency,” but still loses most oxygen.

4.4 Venturi Injectors

How they work:

Use pressure drop to pull gas into flowing water

Typical GTE:

⚠️ 10–25%

Limitations:

Requires high pump energy

Gas bubbles still form and escape

Efficiency highly flow-dependent

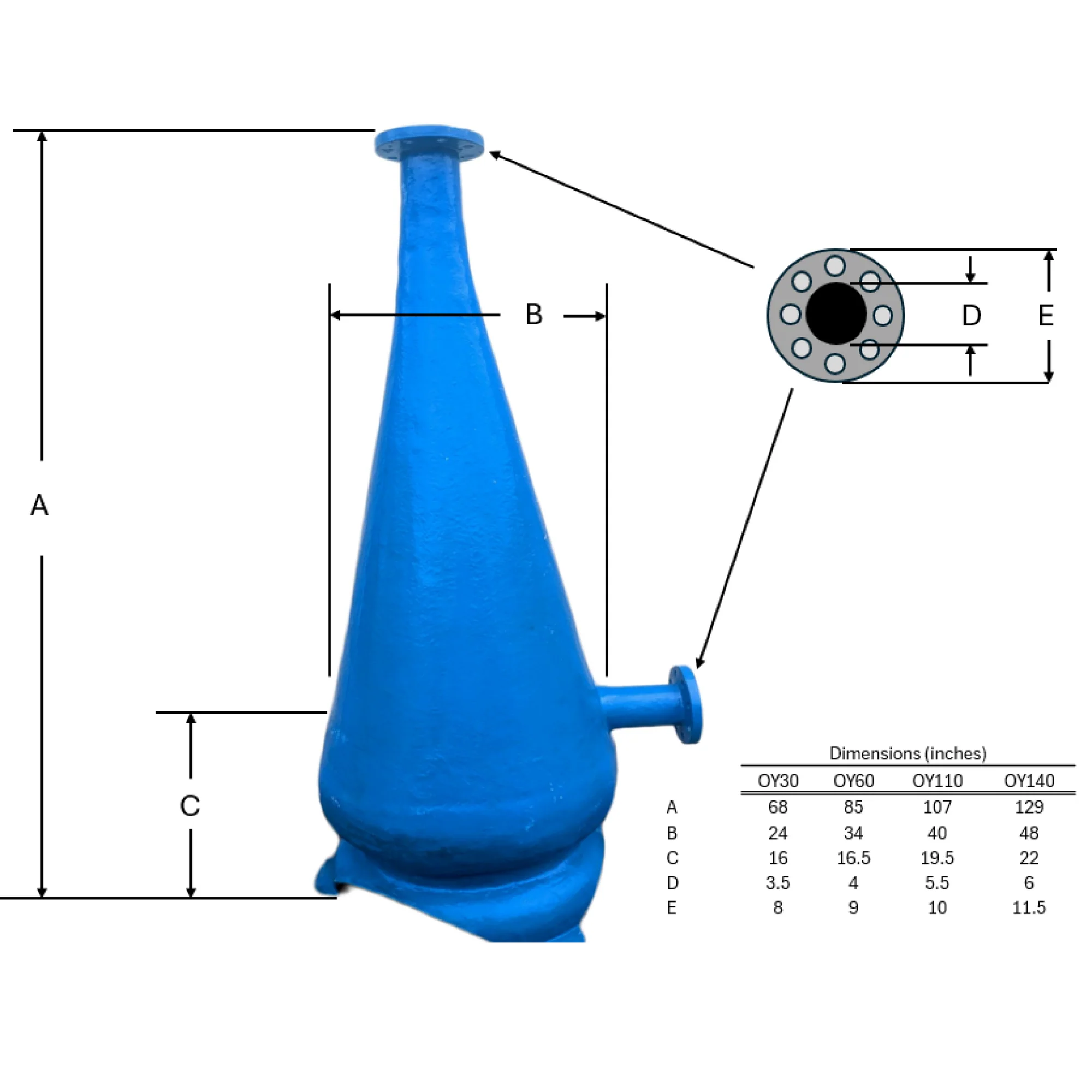

4.5 Pressurized Oxygen Cones / Saturators

How they work:

Dissolve gas under pressure before releasing water

Typical GTE:

✅ 60–90%

Limitations:

High CAPEX

Large footprint

Complex operation

Mainly suitable for large industrial facilities

Strength:

High dissolution — but limited scalability and flexibility.

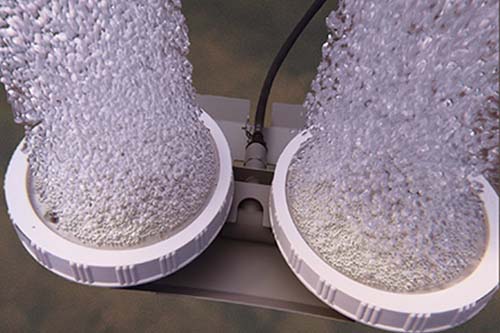

4.6 Nanobubble Technology

How it works:

Generates ultra-fine gas bubbles (<200 nm) that:

Do not rise

Remain suspended for days

Dissolve gas via diffusion, not buoyancy

Typical GTE:

✅ 80–95% (often approaching theoretical maximum)

Why nanobubbles are different (not just “smaller bubbles”)

Nanobubbles:

Have near-zero buoyancy

Possess electrostatic surface charge

Create extremely high gas–liquid interfacial area

Remain stable long enough for full gas dissolution

This shifts oxygenation from:

“bubbles rising and escaping”

to

“gas stored and released inside the water itself”

5. Why GTE Above 100% Saturation Is Possible

Traditional systems aim for 100% DO saturation because excess oxygen escapes as bubbles.

Nanobubbles allow:

200–400% DO saturation

Without visible bubbling

Without rapid off-gassing

We suggest checking out our article about this.

This is critical in:

Hydroponics

Aquaculture

Irrigation reservoirs

Livestock drinking water

Ozone disinfection

6. Energy Efficiency: The Hidden Cost of Low GTE

Low GTE systems compensate by:

Increasing airflow

Increasing pressure

Increasing runtime

Result:

High electricity bills

Equipment wear

Marginal DO improvement

Nanobubble systems achieve higher DO with less gas and less energy, because almost every molecule injected is actually used.

7. Summary Comparison Table

Technology | Typical GTE | Bubble Behavior | Stability | Overall Efficiency |

|---|---|---|---|---|

Surface aerator | 2–5% | Large, instant escape | None | ❌ Very low |

Coarse bubbles | 5–10% | Fast-rising | Low | ❌ Low |

Fine bubbles | 15–30% | Rising | Medium | ⚠️ Moderate |

Venturi | 10–25% | Rising | Medium | ⚠️ Moderate |

Oxygen cone | 60–90% | Dissolved under pressure | High | ✅ High |

Nanobubbles | 80–95% | Non-rising | Very high | ✅ Excellent |

8. Key Takeaway

Gas transfer efficiency is not about how much gas you inject —

it’s about how much stays in the water and does useful work.